India based manufacturer of cotton pads, balls, earbuds, rolls & pleats, bleached cotton fibres and non-woven fleece.

The best cotton products for personal use

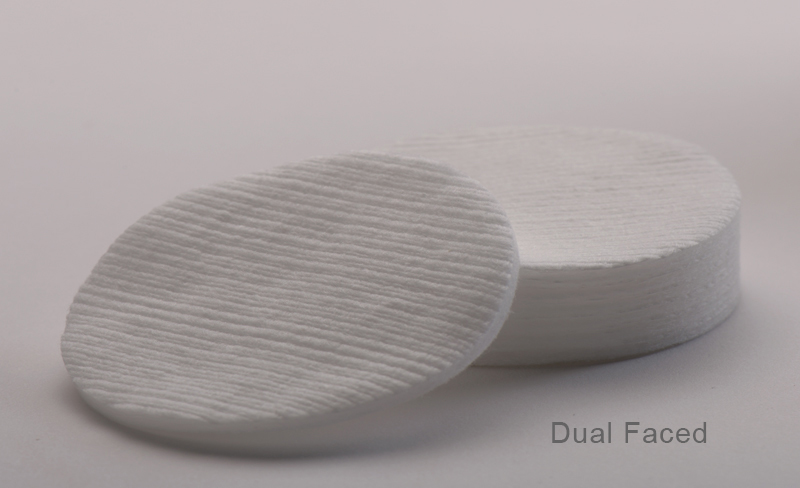

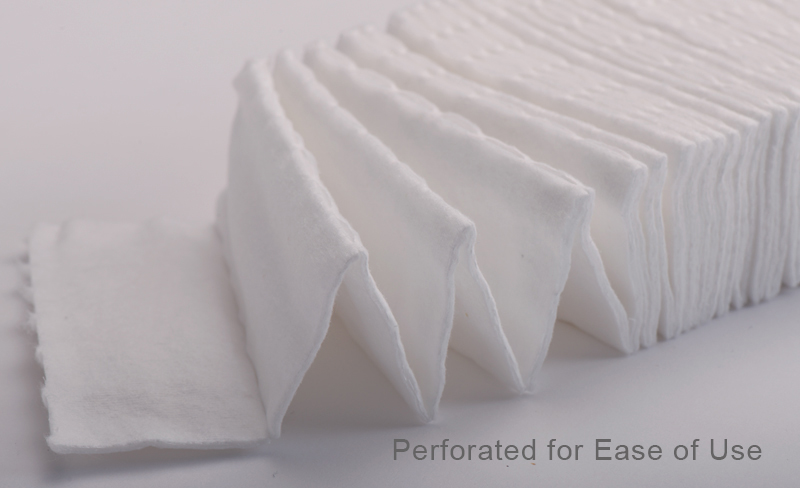

Cotton Pads

We produce cotton pads in all shapes for a range of applications, including baby care, beauty, and healthcare. Our cotton pads can be offered with embossing, side-stitching, open and closed edges. The weight of pads can be varied based on the requirement of the customer. We pioneered the use of hydro-entanglement or water bonding technology for making cotton pads in India. This gives multi-directional strength to the product and ensures “no fibre shedding”. Our state-of-the-art high production spun lace line, helps to ramp up our production capacity for cotton pads and achieve economies of scale. Our fully automated machines punch the cotton pads and pack them into bags (retail packs). Subsequently, these bags are barcoded and prepared to be packed into cartons, after inspection. We use machinery imported from Europe, to convert the printed film (as per the artwork of the customer) into drawstring bags, in which the finished goods are packed. This helps in reducing the lead time for delivery of goods to our customers. Lavino Kapur has GOTS certification to produce pads in various shapes, from 100% Organic cotton.

Cotton Balls

Cotton Rolls & Pleats

Cotton Buds

All our cotton buds are produced from cotton sliver, manufactured in-house. Processing raw cotton to finished goods in-house ensures complete control over the quality of goods produced, while ensuring short lead times. Cotton sliver, which is usually of a lower grammage compared to cotton balls, is wound onto the two ends of either a paper or plastic stem. The weight of the sliver varies according to the cotton bud being produced. Our cotton buds range includes the following:

Standard Cotton Buds

Used to clean the outer surface of the ear and other precise hygiene applications.

Safety Buds for Babies

Used for gentle cleansing. The specially designed tips ensure careful and safe cleansing around baby’s eyes, ears, nose, and navel.

Cosmetic Applicators

The flat end of the applicator is used to apply and blend eye makeup. The pointed end can be used for adding definition to intricate areas around the eyes and lips. Cosmetic buds can also be used for tidying up nail polish.

Bleached Cotton Fibres

Our bleached cotton fibres are widely used in the manufacture of feminine and personal hygiene products, medical products (after sterilization), baby products. They are also used in many other non-woven products, which are converted into finished products for a range of applications. We transform raw cotton into bleached cotton through processes of mechanical cleaning and scouring and bleaching. We use Hydrogen Peroxide (H2O2) for bleaching of cotton fibres as this is one of the eco-friendliest methods of bleaching. The use of special cleaning & bleaching techniques helps us achieve impeccable spotlessness and whiteness, while ensuring the natural properties of cotton are retained in the production process. Post production, bleached cotton fibres are tested in our onsite laboratory to ensure conformance with British, European, Japanese and US pharmacopoeia standards. The bleached, absorbent cotton fibres are compressed into bales weighing about 150 kgs. Each bale is wrapped in laminated fabric neatly bound by self-locking straps. Lavino-Kapur has GOTS certification to produce bleached, absorbent cotton fibres from 100% Organic cotton

Cotton Non-Woven Fleece

Cotton fleece can be used for a variety of cosmetic, hygiene and healthcare (after sterilization) applications. We manufacture top quality cotton non-woven fleece using the highly eco-friendly ‘water bonding’ or hydro entanglement process. Under this process, the use of water pressure provides multi-directional strength to the final product, thus preventing fibre shedding. Lavino Kapur has pioneered the use of hydro entanglement technology in India. Our cotton fleece is produced at an ultra-modern plant, which has been imported from renowned suppliers in Europe. In more ways than one, the non-woven cotton fleece is produced using bleached, absorbent cotton fibres, which are manufactured at our factory, and comply with British, European, Japanese and American Pharmacopeia norms. The cotton fleece can be offered at weights ranging from 60 gsm to 300 gsm. We can also offer cotton non-wovens with different patterning options. Our cotton fleece is packed by shrink wrapping in HDPE. Lavino Kapur has GOTS certification to produce nonwovens from 100% Organic cotton.

Sliver

Packaging

We offer our clients a range of packaging options. Apart from traditional plastic bags made from LDPE and boxes made from Polypropylene (PP), we can package the products in environmentally friendly materials such as 50% Post Consumer Re-cycled Plastic and bio-degradable and compostable material such as Poly Lactic Acid (PLA) or Corn Starch for bags. We can fabricate white and brown paper boxes with/without windows, with/without sleeves. We provide options of blister packaging as well. We can offer cotton buds in paper cans with lids for and cotton pads in dispenser boxes. We also have the capability of manufacturing draw string bags in-house but offer traditional zip lock seals as per our clients’ preference.